Dust Collectors

The blue technique of clearing the world of all breaths.

Dust Collectors

DuClean is an eco-friendly company that cares about the environment.

Filter Type

Meet the filter line optimized for each type of dust collector.

Cartridge Filter (PTFE)

Cartridge Filter (PTFE)

Membrane Filter (PTFE)

Membrane Filter (PTFE)

Aluminum Cartridge Type Antistatic Filter

Aluminum Cartridge Type Antistatic Filter

Membrane Cartridge Type Filter

Membrane Cartridge Type Filter

Flame-retardant filter

Flame-retardant filter

Water-repellent filter

Water-repellent filter

Bag Filters

Bag Filters

Mineral Bag Filter

Mineral Bag Filter

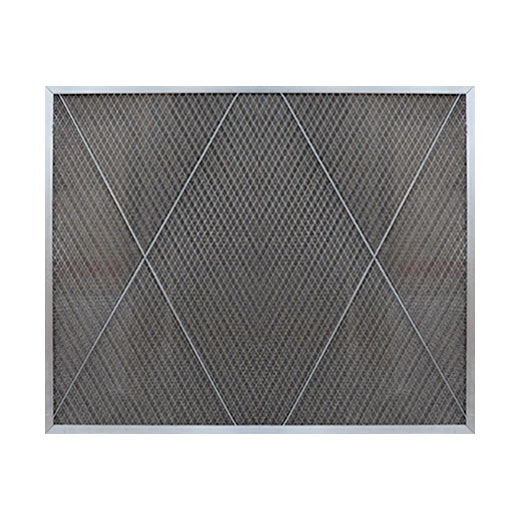

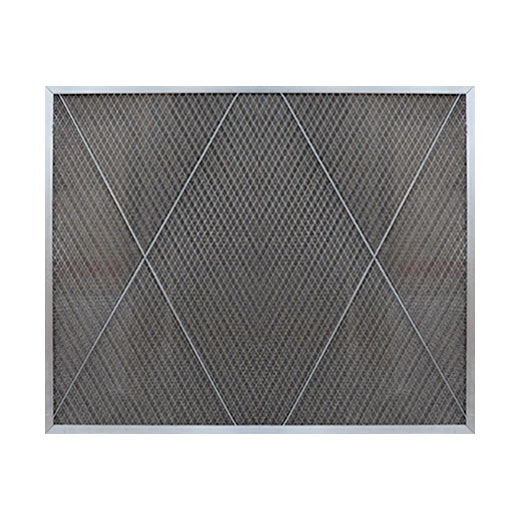

Demister Filter

Demister Filter

Vee Bag Filter

Vee Bag Filter

Pre-Filter

Pre-Filter

Medium filter

Medium filter

Activated Carbon

Activated Carbon

H.E.P.A filter

H.E.P.A filter

U.L.P.A filter

U.L.P.A filter

A.C.F filter

A.C.F filter

Cartridge Filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

- FC SERIES >

- HD SERIES >

Membrane Filter

Membrane Cartridge Filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

- FC SERIES >

- HD SERIES >

Aluminum cartridge type antistatic filter [Antistatic Filter]

Aluminum antistatic filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

Membrane Cartridge Type Filter [Membrain Filter]

Membrane Filter

Field of Use

Filter Features

A normal filter can simultaneously treat fine particles such as fine dust and pollutants that are difficult to remove and static electricity It reduces the risk of fire or explosion. Membrane antistatic filters with high chemical stability can be used in a variety of industries It also helps to extend the life of the filter by reducing dust accumulation on the filter.

Select Option

Applied Equipment

- AP SERIES >

- APD SERIES >

- FC SERIES >

Flame-retardant filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

- APD SERIES >

- FC SERIES >

Water-repellent filter

Field of Use

Filter Features

It prevents water droplets or moisture from penetrating into the filter, so it can withstand environmental stress such as moisture It is possible to filter particles in the air stably even in humid environments.

Select Option

Applied Equipment

- AP SERIES >

- APD SERIES >

- FC SERIES >

Bag Filter

Field of Use

Filter Features

Select Option

- Manual and automatic shaking options are available.

- Antistatic and water repellent options are also available.

- Manual shaking: Shaking handle to remove dust.

- Automatic Shaking: Measuring dust pressure according to filter contamination and automatically exhausting dust

Applied Equipment

- MS SERIES >

- MSR SERIES >

- MST SERIES >

Mineral Bag Filter

Field of Use

Filter Features

Select Option

- Manual and automatic shaking options are available.

- Manual shaking: Shaking handle to remove dust.

- Automatic Shaking: Measuring dust pressure according to filter contamination and automatically exhausting dust

Applied Equipment

- MS SERIES >

- MSR SERIES >

- MST SERIES >

Demister Filter(Stanless steel)

Demister Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

Vee Bag Filter

Vee Bag Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

High Performance Non-woven Fabric Melt Blown

Pre-Filter

Field of Use

Filter Features

Applied Equipment

- ZF SERIES >

- LC SERIES >

Medium filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

Activated Carbon

Field of Use

Filter Features

Applied Equipment

- ACT SERIES >

- LC SERIES >

H.E.P.A Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

U.L.P.A Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

- ZF SERIES >

Activated Carbon Fiber Filter

A.C.F Filter

Field of Use

Filter Features

Applied Equipment

- CHB SERIES >

- OMC-N SERIES >

- - Assembled coal: It is a product produced by extrusion at high pressure and is used for high-concentration gas such as painting, drying facilities, solvent recovery facilities, etc.

- - Creased activated carbon: It has a relatively large surface area and is the most widely used activated carbon in the entire industry, and waste activated carbon is reused after regeneration treatment.

- - Powder activated carbon: Mainly used for bleaching, deodorizing, removing bad taste and impurities of liquid materials and suitable for water treatment

- - Attachment Activated Carbon: Activated Carbon with physical adsorption, chemical reaction, and catalytic action by attaching a chemical reaction and catalytic substance into the pores of general activated carbon

Cartridge Filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

- FC SERIES >

- HD SERIES >

Membrane Filter

Membrane Cartridge Filte

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

- FC SERIES >

- HD SERIES >

Aluminum cartridge type antistatic filter [Antistatic Filter]

Aluminum antistatic filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

Membrane Cartridge Type Filter [Membrain Filter]

Membrane Filter

Field of Use

Filter Features

A normal filter can simultaneously treat fine particles such as fine dust and pollutants that are difficult to remove and static electricity It reduces the risk of fire or explosion. Membrane antistatic filters with high chemical stability can be used in a variety of industries It also helps to extend the life of the filter by reducing dust accumulation on the filter.

Select Option

Applied Equipment

- AP SERIES >

- APD SERIES >

- FC SERIES >

Flame-retardant filter

Field of Use

Filter Features

Select Option

Applied Equipment

- AP SERIES >

- APD SERIES >

- FC SERIES >

Water-repellent filter

Field of Use

Filter Features

It prevents water droplets or moisture from penetrating into the filter, so it can withstand environmental stress such as moisture It is possible to filter particles in the air stably even in humid environments.

Select Option

Applied Equipment

- AP SERIES >

- APD SERIES >

- FC SERIES >

Bag Filter

Field of Use

Filter Features

Select Option

- Manual and automatic shaking options are available.

- Antistatic and water repellent options are also available.

- Manual shaking: Shaking handle to remove dust.

- Automatic Shaking: Measuring dust pressure according to filter contamination and automatically exhausting dust

Applied Equipment

- MS SERIES >

- MSR SERIES >

- MST SERIES >

Mineral Bag Filter

Field of Use

Filter Features

Select Option

- Manual and automatic shaking options are available.

- Manual shaking: Shaking handle to remove dust.

- Automatic Shaking: Measuring dust pressure according to filter contamination and automatically exhausting dust

Applied Equipment

- MS SERIES >

- MSR SERIES >

- MST SERIES >

Demister Filter(Stanless steel)

Demister Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

Vee Bag Filter

Vee Bag Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

High Performance Non-woven Fabric Melt Blown

Pre-Filter

Field of Use

Filter Features

Applied Equipment

- ZF SERIES >

- LC SERIES >

Medium filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

Activated Carbon

Field of Use

Filter Features

Applied Equipment

- ACT SERIES >

- LC SERIES >

H.E.P.A Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

U.L.P.A Filter

Field of Use

Filter Features

Applied Equipment

- OMC SERIES >

- CHB SERIES >

- ZF SERIES >

Activated Carbon Fiber Filter

A.C.F Filter

Field of Use

Filter Features

Applied Equipment

- CHB SERIES >

- OMC-N SERIES >

- - Assembled coal: It is a product produced by extrusion at high pressure and is used for high-concentration gas such as painting, drying facilities, solvent recovery facilities, etc.

- - Creased activated carbon: It has a relatively large surface area and is the most widely used activated carbon in the entire industry, and waste activated carbon is reused after regeneration treatment.

- - Powder activated carbon: Mainly used for bleaching, deodorizing, removing bad taste and impurities of liquid materials and suitable for water treatment

- - Attachment Activated Carbon: Activated Carbon with physical adsorption, chemical reaction, and catalytic action by attaching a chemical reaction and catalytic substance into the pores of general activated carbon